Industrial Plant Automation

2020, International Journal for Research in Applied Science and Engineering Technology IJRASET

https://doi.org/10.22214/IJRASET.2020.5097…

8 pages

1 file

Sign up for access to the world's latest research

Abstract

Now-a-days, marketing demands are increasing continuously. If you are unable to give the required results then it'll be hard to succeed. Our project satisfies this need by using a data analysis by making use of high-end technology. The proposed project is to provide industrial automation which is useful for monitoring and automating the devices for better maintenance. An Arduino Uno is used which monitors the components according to the given message, with the sensed information sent from the sensors. This paper discusses the working of temperature, voltage and product count of the machines. As the automation is Arduino based it easily monitors the temperature changes.

Key takeaways

AI

AI

- The proposed project automates industrial monitoring using Arduino for enhanced maintenance and decision-making.

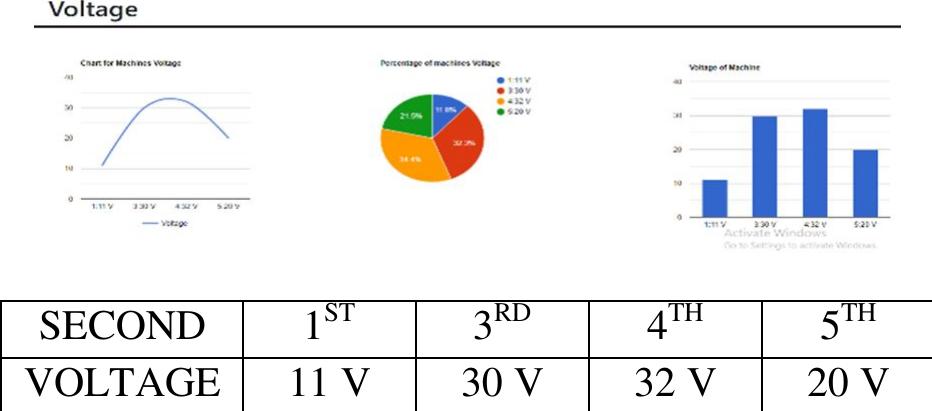

- Sensors measure temperature (LM35), voltage (0-25V), and speed (IR speed sensor) for real-time data collection.

- Automation reduces human labor while improving product quality and production efficiency.

- Threshold limits trigger machine shutdowns to prevent equipment damage and financial loss.

- The system architecture includes web application development using Django for remote data access.

Related papers

International Journal of Engineering Applied Sciences and Technology, 2020

Automation is the process by which the work is done much faster, hassle free, performed more accurately and precisely by reducing manpower and the number of people required. With the help of these automated machines critical jobs which human can't do, can be done very easily and conveniently. The basic necessity of "why automation?" as well as the devices or software which are used for automating the industry is also discussed. Here in this paper we have discussed about PLC, one of the digital computers used for the purpose of automation.

Open Science Journal of Electrical and Electronic Engineering, 2015

Industrial Workers are often prone to accidents in the course of the discharge of their duties especially in high temperature or high frequency areas; hence the need to minimize the rate of exposure of these workers to these precarious environments. This paper discusses a way out of these avoidable scenarios through the design of an automated system, which is capable of measuring parameters such as voltage and temperature in an industrial environment. Two Universal Serial Bus (USB) PIC Microcontrollers were used; one functioned as the Master Controller attached to the Microcomputer and the other as a slave, driven by the Master Controller. The USB PIC Microcontroller was connected by only three wires to the Microcomputer where the I/O pins could be read or set using a simple ASCII protocol sent from a Microcomputer USB port. The communication between the PC and the system was very fast due to the use of a high speed USB V2.0 as the interface having a data transfer rate of 480MBits/s. The use of high-performance Microcontrollers with programmable I/O lines and powerful integrated peripherals reduced the number of electronic components and in turn simplified the entire system. The use of the PIC18F4550 Microcontroller especially improved the acquisition rate performance. It is therefore recommended that a Digital Signal PIC Microcontroller (DSPIC) be used in place of the regular PIC18F4550 Microcontroller for improved processing techniques and so on.

In the last decades, industrial automation has become a driving force in all production systems. Technologies and architectures have emerged alongside the growing organizational structures of production plants. Industrial automation plays an important role in industrial and manufacturing environment. Industrial automation means automatically control of industrial appliances which save money, time also reduce human efforts. Automation devices such as controllers and data systems and/or services. Systems and methods are provided that receive statements or other unit of data interaction from an automation device, provide the statements to an appropriate system or service for processing, and optionally return a response such as a result set. In this paper brief study about the automation, level of automation, Industrial automation and types of industrial automation etc.

DYNA, 2021

The industry 4.0 revolution provides the machines with a sensory and communicational capacity, which allows them to monitor and collect large amounts of information. This kind of data have an impact on planning, maintenance, and management of production, enabling real time reaction, efficiency increase, and the development of predictive and process improvement models. The most recent machines are prepared to communicate with the existing monitoring systems, however, many (around 60%) do not. The objective of this work is to present the proposal of a system for remote monitoring of equipment in real time that meets the requirements of low cost, simplicity, and flexibility. The system monitors the equipment in a simple and agile way, regardless of its sophistication, installation constraints and company resources. A prototype of a system was developed and tested both laboratory conditions and a productive environment. The proposed architecture of the system comprises of a sensor that ...

International Journal of Advance Research Ideas and Innovations in Technology

In our project, we are trying to implement IoT in the manufacturing area for monitoring the industries and obtaining the crucial data that can be used to implement automated decisions using machine learning for the safety of the workers in an industry an increasing the productivity and efficiency of an Industry. Also, we will discuss some the current trends in the Industrial IoT or Industry 4.0 and see If there could be any improvement that can be done in this sector and discuss challenges we can face in implementing IoT and how can be these challenges be addressed. Industry4.0 is a name given to the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things, cloud computing and cognitive computing. Industry 4.0 is considered as the fourth industrial revolution. All these, when implemented to a Manufacturing Industry, can improve the production system and Safety of an Industry.

— Boiler is one of the most important equipment in any power plants which require continuous monitoring and inspection at frequent intervals. There are possibilities of errors at measuring and various stages involved with human workers. So a reliable monitoring system is necessary to avoid catastrophic failure, which is achieved by Programmable Logic Controller & Supervisory Control and Data Acquisition system. This paper outlines the design and development of boiler automation system using PLC, SCADA and sensors. PLC and SCADA interfaced via communication cables. The initial phase of the paper focuses on passing the inputs to the boiler at a required temperature, so as to constantly maintain a particular temperature in the boiler. SCADA is used to monitor the boiler temperature, pressure and water level using different sensors and the corresponding output is given to the PLC which controls the boiler temperature, pressure and water level. If the temperature and pressure inside the boiler exceeds the predefined value then the entire system is shut down. In case of emergency different automated check valves are used to release pressure, steam and inform the concerned authority through alarm. Boiler automation ladder diagram is designed using WPL soft and SCADA design is done by Intouch wonderware.

International Journal of Engineering & Technology

The prospect to build robust industrial systems & applications in the field of RFID, mobile &sensor devices, wireless, Internet of Things (IOT) has been provided. In very modern years many IOT applications have been increasingly developed and deployed. In our day to day life controlling and monitoring plays a major role now a days. Using advanced technologies we can monitor and control everything. Be-cause of high speed internet a wonderful feature that came into picture is Remote access. The main objective of this proposed system is for those who are away from their industry and want to control devices by providing technology oriented and low cost system.

Boiler automation is getting to be mainstream because of its various advantages in industry as the quantity of mischances occurs in the business are expanded in incredible degree. These mishaps are principally caused because of framework or apparatus disappointment or because of sporadic unreliable checking and controlling of the boiler framework. Such mischances winds up Hazardous for human life working with that condition. To evade such mischances occurred because of framework blunder we need to control the framework parameter consequently. The framework proposed in this paper gives propel answer for the checking and controlling of the mechanical Industrial Boiler parameter from anyplace, whenever by utilizing web.

2014

Industries are the biggest workplace all over the world, also there are large number of peoples involves as a worker and most of them are work as a machine operator. There are many systems developed for industrial work place, some of them, monitors machine processes and some do monitoring and control of machine parameters. Such as speed, temperature, production batch count etc. However there is no such system available that provides monitoring of operator during their work is in progress at workplace. This paper proposes the monitoring of the operators and the machines, by Real time Operator -Machine Allocation and monitoring system (Omams). Omams allocates a work machine to worker at entry point itself. It uses automation with RFID and one of the standards of wireless communication method. The system can be industry specific. Through this research paper our approach is to make fair allocation of machine to the operator in industry and reduce hassle for efficiency calculations.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

References (3)

- Kamrul Islam, Weiming Shen, Xianbin Wang, "Wireless Sensor Network Reliability and Security in Factory Automation", Volume: 42, Issue: 6, Nov. 2012

- V. M. Chadeev, N. I. Aristova, "Control of Industrial Automation", November 2017

- Lars Dürkop, Lukasz Wisniewski, Sascha Heymann, Benedikt Lücke, Jürgen Jasperneite, "Analysing the engineering effort for the commissioning of industrial automation systems", September 2015

IJRASET Publication

IJRASET Publication