Transient Simulation of a Metal Cooling Process

Sign up for access to the world's latest research

Abstract

Transient heat conduction is encountered in metallurgical industries where metals are subjected to different heat treatment processes to enhance their physical and chemical properties (e.g. annealing). The actual heat treatment process involves complex heat transfer processes described andsuch problems are preferentially solved using numerical methods. This work studies the transient cooling of a metal plate using a finite volume-based commercial CFD code. The temperature distribution in the metal plate during the cooling process was well predicted for both the explicit and implicit schemes with the maximum error occurring at the boundary nodes.At the constant heat flux boundary x= 0, the numerical model under predicted the temperatures with a maximum error of-0.08 %. At the convective boundary x = 0.135m , the numerical model over predicted the temperatures with a maximum error of 0 .79%. Furthermore more computational time was required in the explicit scheme in contrast to the implicit scheme that required less time. Using the implicit scheme, the calculated time for the plate to attain steady state was approximately 47,000 s.

Related papers

International journal of engineering research and technology, 2013

Many heat transfer applications, such as steam generators in a boiler or air cooling in the coil of an air conditioner, can be modeled in a bank of tubes containing a flowing fluid at one temperature that is immersed in a second fluid in a cross flow at different temperature. Fluids considered in the present study are water and air. Flow is classified as laminar and steady, with Reynolds number between 100-600. In the present paper tubes of different diameters and different mass flow rates are considered to examine the optimal flow distribution. The various static pressures, velocities, and temperatures obtained are reported. Further the problem has been subjected to effect of materials used for tubes manufacturing on heat transfer rate. Materials considered are aluminum, copper and alloys. Results show significant variations between aluminum, copper and alloy as tube materials. Results emphasize the utilization of alloys in place of aluminum and copper as tube material serves better heat transfer with most economic way.

Acta Polytechnica Hungarica, 2020

Quenching of metal products is a complex physical process that is difficult to precisely describe by physical models. The “Heat Transfer Coefficient (HTC)” at the surface of the workpiece is a practical parameter that depends on the nature of the flow, the density, viscosity, and the thermal properties of the cooling liquid, the surface quality, shape, and thermal data of the component under quenching. Normally only numerical techniques are available for its estimation that need huge computational power. However, in the practice, on the basis of approximate quantitative data and some qualitative knowledge, often good and simple approximations can be elaborated for the description of quite complicated problems. In this paper a simple approximation is suggested for modeling the time-dependence of the HTC of an Inconel 600 alloy probe of cylindrical shape used in the standard ISO 9950. Simulation results using moderate computational power are presented to substantiate the suggestion.

ISIJ International

Accelerated cooling (ACC) is one of the key processing steps in the production of Advanced High Performance Steels. In order to obtain thermo-mechanically controlled processed (TMCP) steel products with desired microstructures and mechanical properties, it is necessary to properly adjust the processing parameters of the cooling facility, and therefore it is critically important to quantify the physical process of heat removal by applying water jets on the hot surface of steel. In the present study we propose a mechanistic model for top jet cooling of a moving plate with circular and planar nozzles. The simulation model has been developed based on the extensive experimental database generated with pilot scale runout table tests, and it provides a potentially powerful tool for simulation of cooling of steel strips and plates over the entire length of the cooling facility. KEY WORDS: steel; jet impingement boiling; transient heat transfer; temperature modeling; accelerated cooling; runout table.

Ironmaking & Steelmaking, 2011

The cooling process in the manufacture of long steel products generates residual stresses and bending in the section. This initial state, arising from the cooling bed, influences the final residual stresses and bending at the end of the subsequent processes. Owing to the importance of the cooling process, this paper presents realistic modelling and optimisation using computational fluid dynamics (CFD) and finite element analysis. Computational fluid dynamics rendered it possible to accurately overcome two main problems common to previous cooling models: the realistic modelling of the heat transfer coefficient (especially important when modelling outdoor cooling beds because of the implications of forced convection) and the precise view factor modelling of the different section surfaces (useful when modelling a complex section). After decoupled CFD thermo-analysis, the temperature record of each node in the section was loaded into the finite element stress displacement model. The relevant influence of steel phase transformation was considered applying a combined methodology, involving an ABAQUS user subroutine. Accordingly, accurate residual stresses and bending were obtained. After establishing the models, several strategies were analysed for reducing the residual stresses during the cooling process. Results were successfully validated with experimental data from structural section producers.

2008

In this paper fluid flow and heat transfer are modeled in a corrugated 3D plate heat exchanger geometry with a commercial computational fluid dynamics (CFD) program, Fluent 6.1.22 (Fluent Inc., Lebanon), in order to find out the most realistic heat transfer boundary conditions for a plate heat exchanger. The built-in boundary conditions of Fluent available for this case are Heat flux, Convection and Constant wall temperature. The CFD models are verified with correlations and experimental data obtained by a flat plate test equipment of which parameters can be calculated analytically. Deficiencies are found in all the built-in heat transfer boundary conditions. Heat transfer modeling with CFD in a corrugated plate heat exchanger is problematic because of the assumptions that have to be made when defining the boundary conditions in the complex geometry. The values of the computational parameters have spatial variations and can not be defined explicitly. However, when compared to the ex...

International Journal for Numerical Methods in Engineering, 1991

An advanced boundary element method (BEM) is presented for the transient heat conduction analysis of engineering components. The numerical implementation necessarily includes higher-order conforming elements, self-adaptive integration and a multiregion capability. Planar, three-dimensional and axisymmetric analyses are all addressed with a consistent time-domain convolution approach, which completely eliminates the need for volume discretization for most practical analyses. The resulting general purpose algorithm establishes BEM as an attractive alternative to the more familiar finite difference and finite element methods for this class of problems. Several detailed numerical examples are included to emphasize the accuracy, stability and generality of the present BEM. Furthermore, a new efficient treatment is introduced for bodies with embedded holes. This development provides a powerful analytical tool for transient solutions of components, such as casting moulds and turbine blades, which are cumbersome to model when employing the conventional domain-based methods.

This study aims to determine the effective cooling parameters for the run-out table (ROT) of strip steel in a hot rolling process. Two-dimensional transient heat conduction is developed, including the external force convection and heat source due to translational motion. The strip velocity, cooling water temperature and external fluid velocity are chosen to study the influent parameters during the cooling process. To determine 2-dimensional transient heat conduction in the cooling process of strip steel, numerical methods are applied to solve for the temperature of the strip steel with appropriate boundary conditions. The backward difference formula (BDF) applies to the discretization of a partial differentiation equation (PDE). The parallel sparse direct linear solver (PARDISO) is applied to the computation in the form of a linear algebraic equation built with the Comsol multiphysics software for the heat transfer module. The simulation studies are divided into 12 case studies with three variations subjected to cooling conditions at the ROT. From the results of the simulation study, appropriate parameters to determine the temperature required for strip steel are achieved.

International Journal of Engineering Systems Modelling and Simulation, 2010

Thin slab continuous casting process can be controlled by the water flow rate through the copper mould to obtain the proper shell thickness for a given casting speed. To achieve this, 2D model for the liquid metal flow in the strand and water flow through the mould is developed using stream function and vorticity formulation. The main advantage is faster computation, which is very important for process optimisation, and real-time modelling for process control. The funnel type shape of the mould is efficiently taken into consideration by using body fitted coordinate system. The detailed CFD-based model can be used for analysing the process parameters and variables like heat transfer through the mould flux, casting speed and superheat. The model can be easily adapted for wide range of casting process like slab and billet casting and thin strip casting.

International Journal of Thermal Sciences, 2019

A local heat transfer coefficient (HTC) has been determined for six cases of vertical plates cooling by the water-air assisted sprays. Full cone 60°nozzle operating under pressure of 0.1, 0.25 and 0.4 MPa has been employed. The plates have been made from the Inconel alloy and stainless steel. The Inconel alloy differs to some extend in thermophysical properties from stainless steel. Plate temperature has been measured with thermocouples at 25 points distributed over 1/4 of the cooled surface. The inverse solutions have given HTC as function of surface coordinates and time. The HTC maximum has varied from 3 to 10 kW/(m 2 •K) over water stream zone. The critical heat flux ranging from 600 kW/m 2 to 2.5 GW/m 2 has been obtained depending on pressure, location and plate material. Based on a large set of HTC a model of local HTC as function of pressure, surface temperature and distance from the stagnation point has been developed. The HTC model depends on 15 coefficients which has been determined for Inconel and stainless steel. The HTC model has been validated. Energy extracted from the plate surface and temperature distributions predicted by the model have been compared to data obtained from inverse solutions and temperature measurements. It has been concluded that the model accuracy is sufficient for simulations of water spray cooling of low conductivity steels from 1200°C to 50°C.

Transient Simulation of a Metal Cooling Process.

Akpan, Patrick 1 and Njiofor, Tobenna 2

1 Department of Mechanical Engineering, University of Nigeria, Nsukka

2 Process Systems Engineering, Cranfield University, UK.

* E-mail of the corresponding author: Patrick.akpan@unn.edu.ng; +2348102475639

Abstract

Transient heat conduction is encountered in metallurgical industries where metals are subjected to different heat treatment processes to enhance their physical and chemical properties (e.g. annealing). The actual heat treatment process involves complex heat transfer processes described andsuch problems are preferentially solved using numerical methods. This work studies the transient cooling of a metal plate using a finite volume-based commercial CFD code. The temperature distribution in the metal plate during the cooling process was well predicted for both the explicit and implicit schemes with the maximum error occurring at the boundary nodes.At the constant heat flux boundary x=0, the numerical model under predicted the temperatures with a maximum error of −0.08%. At the convective boundary x=0.135 m, the numerical model over predicted the temperatures with a maximum error of 0.79%. Furthermore more computational time was required in the explicit scheme in contrast to the implicit scheme that required less time. Using the implicit scheme, the calculated time for the plate to attain steady state was approximately 47,000 s. Keywords: Transient simulation, metal cooling, CFD, finite volume and heat treatment.

INTRODUCTION

Transient or time dependent temperature fields appear when the thermal conditions at the boundaries of a body change (Holman, 2010). For instance, if a body with initial constant temperature is placed in an environment at a different temperature, then heat will flow over the surface of the body and its temperature will change over time. The governing equation for heat conduction in cartesian form obtained by applying the first law of thermodynamics to a differential control volume taken from a quiescent, isotropic and incompressible material with temperature dependent material property k(T) is is given in Eq. 1.The heat sources within the thermally conductive body are accounted for by the volumetric heat generation rate (W˙).

ρcp∂t∂T=div[k(T)gradT]+W˙(T,x,t)

Ultimately a new steady state condition will be reach at the end of this time dependent process. The solution of a transient heat conduction problem can be found in three different ways (Baehr and Stephan, 2006):

- By a closed solution of the heat conduction equation fulfilling all the boundary conditions.

- By an experimental method implementing an analogy process.

- By a numerical solution of the heat conduction equation with boundary conditions.

In order to find a closed solution by mathematical functions, the material properties must be assumed to be temperature independent (Cengel, 2003). To ensure that a linear differential equation is produced, the problem is often limited to either conduction without internal heat sources, or the heat generation rate is presupposed to be independent of or only linearly dependent on temperature. In addition, the boundary condition requires a constant or time dependent, but non-temperature dependent heat transfer coefficient h. The following methods have been used in obtaining closed form solutions: separation of variables, superimposing of heat sources and sinks, Green’s theorem and Laplace transformation.

Experimental analogy procedures are based on the fact that different transient processes, in particular electrical conduction, lead to partial differential equations which have the same form as the heat conduction equation. Study is made of an analogous process and the results are then transferred to the thermal conduction process. As a result of the extensive progress in computer technology, this method has very little practical importance today (Baehr and Stephan, 2006).

The numerical solution of a transient heat conduction problem is of particular importance when temperature dependent material properties or bodies with irregular shapes or complex boundary conditions, for example a temperature dependent h, are present. In such cases a numerical solution is generally the only choice of solution.

The application possibilities for numerical solutions haveincreased considerably since the introduction of computers. Computational Fluid Dynamics (CFD) numerical tools are based on any of these three discretization methods - finite difference (FD), finite element (FE), and finite volume (FV) (Blazek, 2001; Chung, 2002 and Njiofor, 2009) .

The FV method is a Control volume based technique of numerical discretisation. It offers several advantages (including its conservativeness and robustness) that make it particularly attractive for use in both academic and commercial CFD applications. It is also well suited for investigating diffusion problems. It implements the following computational steps: (a)Mesh generation entailing the division of the domain of interest into discrete control volumes, (b) Integration of the governing equations on the individual control volumes to construct algebraic equations for the discrete variables (the unknowns) such as pressure, velocity, temperature, and conserved scalars. © Linearization of the discretised equations and solution of the resulting linear system of equations to yield updated values of the dependent variables (Njiofor, 2009, Eymard et. al., 2000 and Versteeg and Malalasekara, 2007).

Heat treatment processes are used in metallurgical industries to enhance the physical and chemical properties (e.g. annealing) of metals. The heat treatment process involves complex heat transfer processes described by highly-nonlinear partial differential equation such that closed form solution can only be obtained by making simplifying assumptions. Such problems are preferentially solved using numerical methods.

This work studies the transient cooling of a metal plate using a finite volume-based commercial CFD code. The objective of this work is to demonstrate how to solve a transient conduction heat transfer problem by using a finite volume approach.

MATERIAL AND METHODS

The numerical simulation was done using a commercial CFD tool Ansys Fluent version 12.1 (Fluent Inc., 2006) and the results of the simulation were compared with analytical solutions.

Problem Description

The simplest problems in transient heat conduction are problems involving the calculation of a temperature field T=T(x,t), which changes with time only in the x− direction. A further requirement is that there are no sources of heat generation. Such problems are known as linear heat flow problems. A typical example is the annealing process. Annealing in metallurgy and material science is a heat treatment process that alters the properties of a material achieved by heating to above the re-crystallization temperature and maintaining at a suitable temperature, before cooling uniformly in a fluid. Here the interest is in the cooling process and the case to be investigated is the transient cooling of a steel plate.

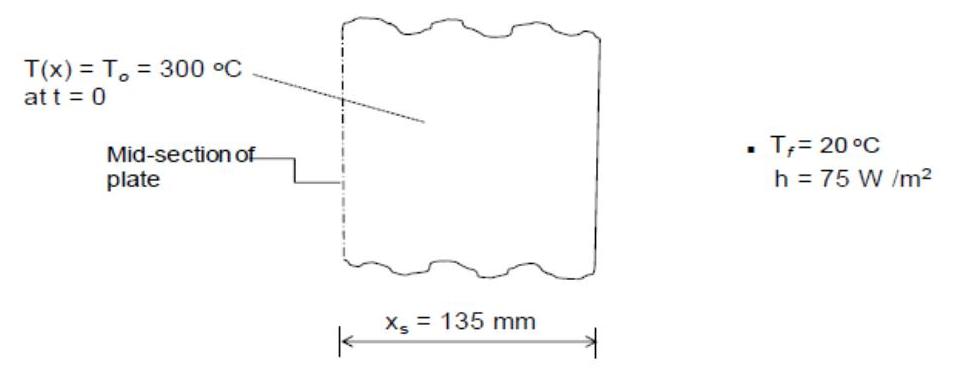

The steel plate investigated is shown in Figure 1 and has thermal conductivity and diffusivity of 15 W/mK and 3.75×10−6 m2/s respectively. It is 270 mm thick and has a constant initial temperature, To=300∘C. At time t>0 the plate is brought into contact with a fluid which has a temperature Tf=20∘C that is constant with respect to time. The heat transfer coefficient at both surfaces of the plate is h=75 W/m2 K. The temperatures during the cooling of the plate are to be numerically determined. Simple initial and boundary conditions were intentionally chosen for comparison of results. Due to the symmetrical nature of the problem, it is sufficient to consider only one half of theplate i.e. xs=0.135 m (see Figure 1). Its left hand surface can be taken to be adiabatic, while heat is transferred to the surrounding fluid from the right surface.

Figure 1 Schematic diagram of longitudinal section through the mid-section of the steel plate (Baehr and

Stephan, 2006)

Grid Generation and Simulation Details

The grid used for this work was generated using GAMBIT and measures 0.3 m×0.135 m (see Figure 2). The spacing between the nodes Δx is 0.015 m .

Boundary Conditions and Discretization

In Figure 2 the mid-section of the plate (surface AB ) was assigned a zero heat flux boundary condition (adiabatic plane). As the problem is one-dimensional, the two surfaces, BC and AD were also assigned zero heat flux while surface CD was assigned convective boundary condition with the heat transfer coefficientand fluid temperature set equal to 75 W/m2 K and 293.15 K(20∘C) respectively.

Figure 2 Steel plate geometrical grid model.

The central differencing scheme was used to discretize the diffusive fluxes in the heat conduction equation. The temperature at the nodes was initialized to 773.15 K(200∘C). Since the problem is unsteady, time marching was implemented using both the explicit and implicit schemes.

Explicit scheme

The time step for the first-order explicit method is subject to the condition (Badr, 2010 and Cengel, 2003) given in (Eq. 2) as:

Δt<ρcp2k(Δx)2<2π(Δx)2

Using this criterion, the limit on time step for time marching was determined as 30 s . A time step of 20 s was first used to run the simulation before using the value given by the limit so as to be able to compare the results obtained using a time step of 20 s to that obtained using 30 s time step. For each time step, convergence was declared when the normalized residual of the applicable heat diffusion equation (also energy equation) became less than 10−6.

Implicit scheme

As the implicit scheme is unconditionally stable, any time step can be used for it (Badr, 2010 and Cengel, 2003) . However, a time step of 20 s was first used to run the simulation before using 30 s in order to compare the results obtained using the two time steps and also compare results obtained with a time step of 30 s to that from the explicit scheme. Finally, convergence was declared when the normalized residual of the applicable heat conduction equation became less than 10−6 as was the case in the explicit scheme.

RESULTS AND DISCUSSION

The exact solution for the problem is given in Baehr and Stephan (2006)as

T(x,t)=Tf+[Te−Tf][i=1∑∞CiCas(λixgx)exp(−λi2xg2πt)]

Where xg is half the plate’s thickness, λi are the eigenvalues of the problem given by the roots of the equation.

Tωnλ=λπt

and Ci are coefficients calculated as

Ci=λi+sinλicosλi2sinλi

Explicit Scheme

The results for the first 15 consecutive time steps are shown in Table 1 while the contours of temperature plot at t =960 s is shown in Figure 3. It can be seen from Table 1 that the temperature of the steel plate decreased with each forward march in time. The temperature drop increased from the mid-section to the outer surface of the plate with the largest drops occurring at the boundary node in contact with the fluid. Also, a look at the table shows that the temperature response at nodes inside the plate is very minimal. This behavior is attributed to the relationship between the rate of change of temperature of the plate and its thermal diffusivity seen from the general heat conduction equation (Eq.1).

According to the equation, the change of temperature with time, ∂T/∂ε at each point inside the steel plate is proportional to the thermal diffusivity. Thus the thermal diffusivity has a direct effect on how quickly the temperature changes inside the plate and as its value is small in this case study ( 3.75×10−6 m2/s ), the rate of change of temperature will also be small. The contours of temperature plot (Figure 3) revealed the existence of temperature gradients in the plate, with the mid-section having the highest temperature.

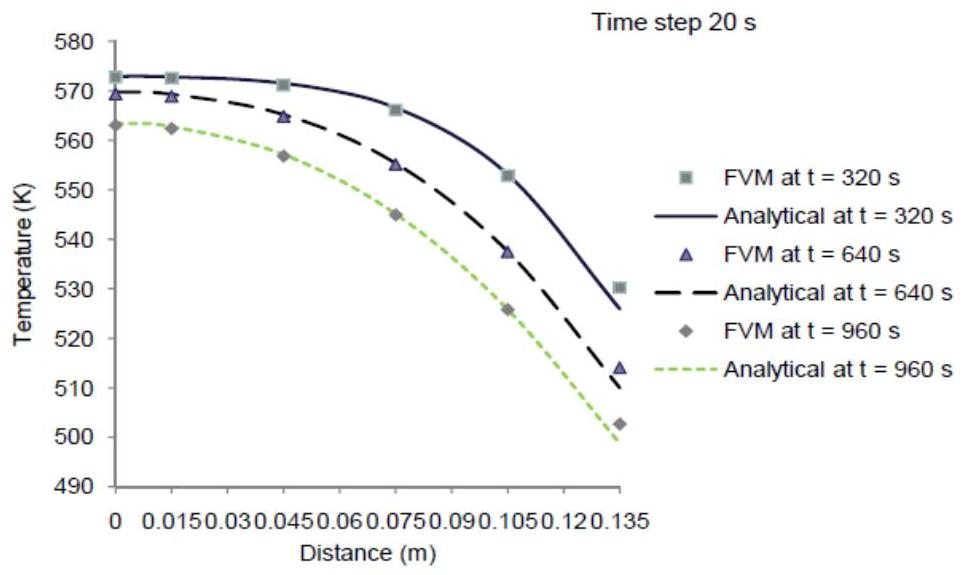

A comparison of the numerical and analytical results at 320 s,640 s and 960 s from the start of the cooling process is illustrated graphically in Figure 4. The error analysis clearly shows that the results are in good agreement with the analytical solution except at the convective boundary where maximum error occurred. This can be attributed to the coarseness of the grid used for the computation. The use of fine grid around the nodes will further reduce the errors to very low values as fine grid captures the large temperature gradients occurring at boundary nodes better than coarse grid.

Table 1 Results showing temperature distribution in the plate (explicit method with time step of 20 s )

| Time step |

Time (s) |

Distance from the mid-section to the outer surface of the plate | |||||

|---|---|---|---|---|---|---|---|

| x=0.0 | x=0.015 | x=0.045 | x=0.075 | x=0.105 | x=0.135 | ||

| 0 | 0 | 573.15 | 573.15 | 573.15 | 573.15 | 573.15 | 573.15 |

| 1 | 20 | 573.15 | 573.15 | 573.15 | 573.12 | 572.49 | 562.95 |

| 2 | 40 | 573.15 | 573.15 | 573.14 | 573.04 | 571.45 | 558.77 |

| 3 | 80 | 573.15 | 573.15 | 573.13 | 572.89 | 570.19 | 555.25 |

| 4 | 100 | 573.15 | 573.15 | 573.11 | 572.66 | 568.81 | 552.21 |

| 5 | 120 | 573.15 | 573.14 | 573.06 | 572.36 | 567.38 | 549.52 |

| 6 | 140 | 573.14 | 573.13 | 573.01 | 571.99 | 565.94 | 547.09 |

| 7 | 160 | 573.13 | 573.12 | 572.92 | 571.56 | 564.50 | 544.88 |

| 8 | 180 | 573.12 | 573.10 | 572.82 | 571.08 | 563.08 | 542.83 |

| 9 | 200 | 573.10 | 573.08 | 572.69 | 570.55 | 561.69 | 540.93 |

| 10 | 220 | 573.08 | 573.04 | 572.54 | 569.99 | 560.33 | 539.15 |

| 11 | 240 | 573.04 | 573.00 | 572.36 | 569.39 | 559.00 | 537.48 |

| 12 | 260 | 573.00 | 572.94 | 572.16 | 568.77 | 557.71 | 535.89 |

| 13 | 280 | 572.95 | 572.87 | 571.94 | 568.13 | 556.45 | 534.38 |

| 14 | 300 | 572.89 | 572.79 | 571.70 | 567.47 | 555.22 | 532.95 |

| 15 | 320 | 572.81 | 572.69 | 571.43 | 566.80 | 554.03 | 531.57 |

Figure 3 Contours of temperature at t=960 s (explicit method. time step 20 s )

Figure 4 Comparison of numerical and analytic solutions at different times (explicit method)

Figure 5 Comparison of result obtained using different time step values (explicit method)

Figure 5 compares the solution when time steps of 20 s and 30 s are used at time t=960 s. The previous result with a time step of 20 s and the exact solution are also shown for comparison. As the figure illustrates, there is

no significant difference between the values obtained for the 20 s and 30 s time steps as a result of the low temperature response of the plate.

Implicit Scheme

From Figure 6, it can be seen that the solution using implicit scheme compare favourably with analytical solution. In order to assess the performance of both the explicit and implicit schemes, the analytical solution together with explicit and implicit solutions at t=960 s obtained using a time step of 30 s is shown in Figure 7. Though the differences between the two methods in this case study were not significant due to the low thermal response of the plate, the explicit scheme is known to give unrealistic oscillations at any time step greater than the limit imposed by Eq. 2 while the implicit method tolerates much larger time steps.

Figure 6 Comparison of numerical and analytical solutions at different times (implicit method)

For instance, simulation using the implicit scheme with a time step of 80 s gave results that compared favorably with analytical results as Table 2 illustrates though with higher error values as when compared to results obtained using a lower time step. This is the key advantage of the implicit scheme of time discretization.

Figure 7 Comparison of explicit and implicit solutions for time step of 30 s

Table 2 Comparison of numerical and analytical solutions at different times (implicit method at a time step 80s)

| Distance (m) |

Temperature | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Time =320 s | Time =640 s | Time =960 s | |||||||

| FVM∗( K) | Alt ∗∗( K) | Error (%) | FVM ∗( K) | Alt ∗∗( K) | Error (%) | FVM ∗( K) | Alt ∗∗( K) | Error (%) | |

| 0.000 | 572.40 | 572.94 | −0.09 | 568.83 | 569.79 | −0.17 | 562.66 | 563.47 | −0.15 |

| 0.015 | 572.25 | 572.81 | −0.10 | 568.39 | 569.29 | −0.16 | 562.01 | 562.76 | −0.13 |

| 0.045 | 570.76 | 571.50 | −0.13 | 564.54 | 565.19 | −0.12 | 556.67 | 557.11 | −0.08 |

| 0.075 | 565.97 | 566.56 | −0.10 | 555.28 | 555.34 | −0.01 | 545.16 | 545.09 | 0.01 |

| 0.105 | 553.50 | 553.09 | 0.74 | 538.08 | 537.52 | 0.10 | 526.31 | 525.80 | 0.10 |

| 0.135 | 531.42 | 525.92 | 1.05 | 514.85 | 509.99 | 0.95 | 503.27 | 498.75 | 0.90 |

*FVM - Finite Volume Method results **Alt - Analytical results

However, since the accuracy of the implicit scheme used for this study is only first-order in time, realistic time steps are needed to ensure the accuracy of results. For the explicit scheme, it is very computational expensive to try to divide the computational grid into fine grid as the time step limit will also become very small. For example, with the division of the computational domain into 36 parts, the time step limit for the explicit scheme becomes 1.875 s which will require more computational time assuming that the temperature distribution at steady state is to be determined. This is the reason why the implicit scheme is recommended for general purpose transient calculations because of less computational time and unconditional stability. However, the implicit scheme requires more computer core memory as nodal equations are solved simultaneously at each time step in contrast to the explicit scheme where the nodal equations are solved sequentially at each time step.

Using the implicit scheme with a time step of 20 s , the transient temperature response of the steel plate for t>0 was calculated and the results for the two boundary nodes are shown in Figure 8. It can be seen from Figure 8 that the steel plate experienced steep negative temperature gradients from the commencement of the cooling process till about 20000 seconds later when marginal temperature gradients were observed. Further probing revealed that it took more than 13 hours for the plate to attain steady state. This means that the plate lost heat at a minimal rate due to the low convective heat transfer coefficient between it and the surrounding fluid.

Figure 8 Transient temperature response of the steel plate

CONCLUSION AND RECOMMENDATION

Conclusion

The finite volume method is well suited for studying transient heat conduction as it gives results that are very close to analytical ones (where they exist). The differences between results obtained using the explicit and implicit method of time discretization for the problem considered in this work were not much given the low temperature response of the plate. However, the explicit method has a time step limitation which makes it computational expensive for studying transient heat conduction problems in particular and CFD application in general where fine mesh is often used to run simulations.

The finite volume method having been successfully used to investigate simple diffusion problems can also be used to study heat conduction problems with no known exact solution (steady and unsteady multi-dimensional problems with complicated geometries and boundary conditions). However, it should be pointed out that the finite volume method being a numerical tool often requires a great deal of programming, memory, and computing time which should not be underestimated.

Recommendation

The heat conduction problem considered in this work was a simple heat transfer case. It was chosen for the purpose of comparison with analytical solutions. A thorough investigation of the suitability of the finite volume method for heat transfer problems involving heat transfer by conduction is being suggested for future work as there is currently limited treatment using the method in the literature. This willhelp to expand current knowledge on the method and also lead to further improvement of the method. Studies involving assessment of the performance of the three numerical discretization methods (finite difference, finite element and finite volume) in relation to the solution of heat transfer problems are also being proposed.

The central differencing scheme used in the discretization of the diffusive fluxes in the general transport equation is second-order accurate. In order to improve the accuracy of discretization process, differencing schemes with higher-order accuracy is needed hence it is being suggested that more research should be made towards developing differencing schemes with higher-order accuracy.

REFERENCES

Badr, O. (2010) Heat transfer lecture note: Presented at Cranfield University, UK. Unpublished.

Baehr, H. D. and Stephan, K. (2006). Heat and mass transfer, 2nd Ed. Springer, Berlin.

Blazek, J. (2001). Computational fluid dynamics: principles and applications. Elsevier Science, Oxford.

Cengel Y.A., Heat Transfer: A Practical Approach, 2nd ed., McGraw-Hill, 2003

Chung, T. J. (2002). Computational fluid dynamics.Cambridge University Press, Cambridge.

Eymard, R., Gallouet, T. and Herbin, R. (2000).Finite volume methods.Handbook of Numerical Analysis, 7, 713−1020.

Fluent Inc. (2006).Fluent 6.3 user guide documentation. Fluent Inc., Lebanon.

Holman, J. P. (2010). Heat Transfer, 10th Ed. McGraw-Hill, New York

Njiofor, M. T. (2009). Tool for numerical discretisation: finite Volume method for diffusion problems. Cranfield University, UK. MSc Thesis Unpublished.

Versteeg, H. K. and Malalasekera, W. (2007).An introduction to computational fluid dynamics: The finite volume method, 2nd Ed. Pearson Education, Harlow,England.

ACKNOWLEDGEMENT

The authors wish to thank the Nigerian government who through the Petroleum Technology Development Fund (PTDF) sponsored this research.

NOMENCLATURES

| Symbols | Definition | Units |

|---|---|---|

| ρ | Density | [Kg/m3] |

| cp | Specific heat at constant pressure | [J/kgK] |

| T | Temperature | [K] |

| t | Time | [s] |

| u | Velocity | [m/s] |

| x | displacement in x rectangular coordinate | [m] |

| k | Thermal conductivity | [W/mK] |

| W˙ | Volumetric heat generation rate | [W/m3] |

| h | Heat transfer co-efficient | [W/m2 K] |

| Tf | Temperature of ambient fluid | [K] |

| Tb | Initial temperature of metal plate | [K] |

| xs | Half the metal plate thickness | [m] |

| λi | Eigenvalues of the problem | [−] |

| Bι | Biot number | [−] |

References (9)

- Badr, O. (2010) Heat transfer lecture note: Presented at Cranfield University, UK. Unpublished.

- Baehr, H. D. and Stephan, K. (2006). Heat and mass transfer, 2nd Ed. Springer, Berlin.

- Blazek, J. (2001). Computational fluid dynamics: principles and applications. Elsevier Science, Oxford.

- Cengel Y.A., Heat Transfer: A Practical Approach, 2 nd ed., McGraw-Hill, 2003

- Chung, T. J. (2002). Computational fluid dynamics.Cambridge University Press, Cambridge.

- Eymard, R., Gallouet, T. and Herbin, R. (2000).Finite volume methods.Handbook of Numerical Analysis, 7, 713-1020.

- Fluent Inc. (2006).Fluent 6.3 user guide documentation. Fluent Inc., Lebanon.

- Holman, J. P. (2010). Heat Transfer, 10 th Ed. McGraw-Hill, New York Njiofor, M. T. (2009). Tool for numerical discretisation: finite Volume method for diffusion problems. Cranfield University, UK. MSc Thesis Unpublished.

- Versteeg, H. K. and Malalasekera, W. (2007).An introduction to computational fluid dynamics: The finite volume method, 2nd Ed. Pearson Education, Harlow,England.

Patrick Akpan

Patrick Akpan