Automatic recognition of welding defects in real-time radiography

1990, NDT International

https://doi.org/10.1016/0308-9126(90)90109-2…

6 pages

1 file

Sign up for access to the world's latest research

Abstract

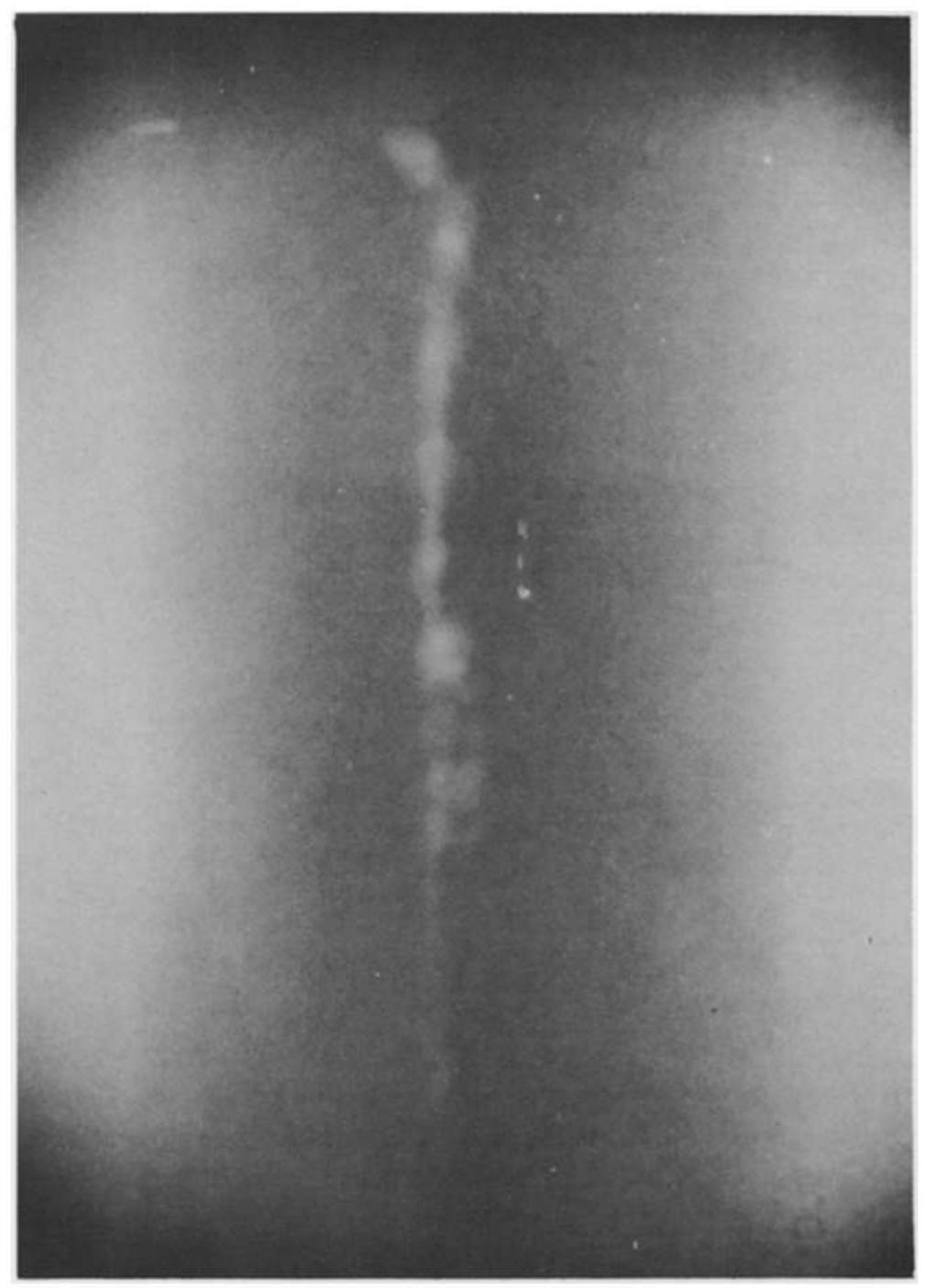

This paper describes a real-time radiography configuration for the automatic inspection of welds. The optimal geometrical imaging configuration is evaluated and discussed in relation to conventional film radiography. For the automatic inspection of X-ray images, a two-step analysis was adopted: a fast search for defective regions, followed by fine identification and location of defects. Two different algorithms, based on the relative irregular behaviour of a defect, were develoPed for the fast search procedure. The second step, fine identification, can be achieved by a sequential similarity detection algorithm or by a thresholding algorithm. The different methods were applied to various X-ray images of welds and the automatic inspection was evaluated and compared with visual inspection.

Related papers

Materials Research, 2003

The use of X-ray as an inspection technique to ensure the integrity of industrial products dates from the beginning of the 20 th century. Therefore, it is a tool of non-destructive inspection widely known. Nowadays, however, there are several researches forward on the optimization of ...

Machgine Graphics & Vision, Vol. 15 N° 3/4, 2006

In non destructive testing by radiography, a perfect knowledge of the weld defect shape is an essential step to appreciate the quality of the weld and make decision on its acceptability or rejection. Because of the complex nature of the considered images, and in order that the detected defect region represents the most accurately possible the real defect, the choice of thresholding methods must be done judiciously. In this paper, performance criteria are used to conduct a comparative study of thresholding methods based on gray level histogram, 2D histogram and locally adaptive approach for weld defect detection in radiographic images.

Ndt & E International, 2002

Radiographic testing is a well-established non-destructive testing method to detect subsurface welding defects. In this paper, an automatic computer-aided identification system was implemented to recognize different types of welding defects in radiographic images. Imageprocessing techniques such as background subtraction and histogram thresholding were implemented to separate defects from the background. Twelve numeric features were extracted to represent each defect instance. The extracted feature values are subsequently used to classify welding flaws into different types by using two well-known classifiers: fuzzy k-nearest neighbor and multi-layer perceptron neural networks classifiers. Their performances are tested and compared using the bootstrap method. q

cerc.wvu.edu

One of the professional domains in industry is weld inspection which deals with investigating the inside or outside (surface) of the weld to trace any defects which may cause failure in the system. Likewise, one of the methods of weld inspection is radiographic film interpretation (RI). In this method the specific weld will be captured in radiographic films and then an inspector will interpret them to identify any defects similar to the job that an orthopaedist does.

In this paper, a method for the detection and classification of defects in weld radiographs is presented. The method has been applied for detecting and discriminating discontinuities in the weld images that may correspond to false alarms or defects such as worm holes, porosity, linear slag inclusion, gas pores, lack of fusion or crack. A set of 43 descriptors corresponding to texture measurements and geometrical features is extracted for each segmented object and given as input to a classifier. The classifier is trained to classify each of the objects it into one of the defect classes or characterize it as non-defect. Three fold cross validation was utilized and experimental results are reported for three different classifiers (Support Vector Machine, Neural Network, k-NN).

2011

Non Destructive Evaluation (NDE) Methods, in particular Digital Radiography(DR), incorporated with Automatic Defect Recognition (ADR) ,for industrial applications is a rapidly progressing area of research across the globe. Though ADR technology has been well established for Digital Radiographic inspection of cast and machined components, ADR is still considered a challenge in the case of many types of weld joints, mainly due to the nonuniformity in the radiographic images of weld joints. This paper introduces an indigenously developed Automatic Defect Recognition System for Real Time Radioscopy (RTR) of Straight Tube Butt Weld(STBW) joints, which are the critical joints of tubular components like Economiser,Super heater and Reheater of a Boiler.RTR system for inspection of STB welds consists of a constant potential X-Ray equipment with swiveling arrangement, as the X-Ray source, Digital Flat Panel (DFP) as the Imaging device with it’s associated Image acquisition and Review Software...

… of 12th European conference on non- …, 2006

A reliable detection of defects in welded joints is one of the most important tasks in non-destructive testing by radiography, since the human factor still has a decisive influence on the evaluation of defects on the film. An incorrect classification may disapprove a piece in good conditions or approve a piece with discontinuities exceeding the limit established by the applicable standards. The progresses in computer science and the artificial intelligence techniques have allowed the welded joint quality interpretation to be carried out by using pattern recognition tools, making the system of the weld inspection more reliable, reproducible and faster. In this work, we develop and implement algorithms based on statistical approaches for segmentation and classification of the weld defects. Because of the complex nature of the considered images and so that the extracted defect area represents the most accurately possible the real defect, and that the detected defect corresponds as well as possible to its real class, the choice of the algorithms must be very judicious. In order to achieve this, a comparative study of the various segmentation and classification methods was performed to demonstrate the advantages of the ones in comparison with the others giving to the most optimal combinations.

Substantial research has been performed on automated detection and classification of welding defects in continuous welds using X-ray imaging. Typically, the detection follows a pattern recognition schema (segmentation, feature extraction and classification). In computer vision community, however, many object detection and classification problems, like face and human detection, have been recently solvedwithout segmentation-using sliding-windows and novel features like local binary patterns extracted from saliency maps. For this reason, we propose in this paper the use of sliding-windows with the mentioned features to perform automatically the automated detection of welding defects. In the experiments, we analyzed 5000 detection windows (24x24 pixels) and 572 intensity features from 10 representative X-ray images. Cross validation yielded a detection performance of 94% using a support vector machine classifier with only 14 selected features. The method was implemented and tested on real X-ray images showing high effectiveness. We believe that the proposed approach opens new possibilities in the field of automated detection of welding defects.

Albaha University Journal of Basic and Applied Sciences, 2017

Technological development accompanied the need to get a high-quality welding. In this research, an automatic technique is introduced to detect, recognize and classify welding defects in radiographic (x-ray) images, using texture features. Image processing techniques, including converting color images to grayscale, filtering and resizing images were applied to help in the image array of weld images and welding defect detection. Therefore, a proposed program was built in-house to automatically classify and recognize the most common types of welding defects met in practice. The introduced technique has been tested on eleven welding defects which are: center line crack, cap undercut, elongated slag lines, lack of interpass fusion, lack of root penetration, lack of side wall fusion, misalignment, root crack, root pass aligned, root undercut, and transverse crack (n = 35 for each). The overall average discrimination rate is about 94.29%. The introduced technique can find promising application of digital image processing technique to the field of welding defect inspection compared with traditional methods.

NDT & E International, 2006

It is necessary to detect suspected defect regions in the radiographic weld images to find the type of flaw and its causative factors. This requires processing of radiographic images by a suitable approach. This paper presents an approach to process these radiographic weld images of the weld specimens considering morphological aspects of the image. The proposed approach first determines the flaw boundaries by applying the Canny operator after choosing an appropriate threshold value. The boundaries are then fixed using a morphological image processing approach i.e. dilating few similar boundaries and eroding some irrelevant boundaries decided on the basis of pixel characteristics. The flaws detected by this approach are categorized according to their properties. q

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

References (8)

- Murphy, W.J.Jr., Nutter, R.L. and Patricelli, F. 'Automated X-ray inspection of composites at Northrop Aircraft' Proc llth World Conf. on NDT (1985) pp 566-570

- Dick, P. and Smith, I. 'Real-time radiography as an inspection tool on complex electronic assemblies' Proc l lth World Conf on NDT (1985) pp 571-575

- Hahnahaw, R. 'X-ray real-time imaging for weld inspection: IIW 3rd progress report' Brit J NDT 29(6) (1987). pp 426-428

- Daum, W., Rose, P., Heidt, H. and Builtjes, J.H. 'Automatic recognition of weld defects in X-ray inspection' Brit J NDT 29(2) (1987) pp 79-82

- Eckelt, B., Meyendorf, N., Morgner, W. and Richter, U. 'Use of automatic image processing for monitoring of welding process and weld inspection' Proc 12th Worm Conf on NDT (1989) pp 37-41

- Rokhlin, S.I. 'In-process radiographic evaluation of welding' Mater Eval 47 (1989) pp 219-224

- Harms, A.A. and Zeiilinger, A. 'A new formulation of total unsharpness in radiography' Phys Med Biol 22( 1 ) (1977) pp 70-80

- Barnea, D.I. and Silverman, H.F. 'A class of algorithms for fast digital image registration' IEEE Trans Computers C-21(2) (1972) pp 179-186

ApaartiSebuahnama Saya

ApaartiSebuahnama Saya