EVSE Simulator: A backbone for EV Infrastructure

2023, International Journal of Innovative Research in Computer and Communication Engineering

https://doi.org/10.15680/IJIRCCE.2023.1105070…

10 pages

1 file

Sign up for access to the world's latest research

Abstract

n developing country like India automotive industry growing rapidly. Growing automotive industry create pollution so government is taking initiative to curb the pollutions through Electric Vehicles. Electric vehicles (EVs) produce zero emissions at the tailpipe, which means that they do not release any pollutants or greenhouse gases into the air. This is in contrast to traditional gasoline-powered vehicles, which are a major source of air pollution and contribute to climate change. By reducing air pollution, EVs can help to improve air quality and protect the health of both humans and wildlife.However, one of the challenges with EV charging infrastructure in India is the lack of a comprehensive and coordinated strategy for its development. Currently, there are a number of different players involved in the development and operation of charging infrastructure, including government agencies, private companies, and electric utilities. This can lead to a fragmented and unevenly distributed charging network, which can be a significant hindrance for EV owners.Manufacturing of Electric vehicle supply equipment(EVSE) is complicated but its more complex to simulate therefore EVSE manufacturer want proper simulator that can measure the capacity, duty cycle, frequency and state change of it. This article includes all the parameter that EVSE manufacture want that can measure by simulator.

Related papers

2018 IEEE International Telecommunications Energy Conference (INTELEC), 2018

Electric vehicles (EV) are rapidly invading the market, since they are clean, quiet and energy efficient. However, there are many factors that discourage EVs for current and potential customers. Among them, driving range is one of the most critical issues: running out of battery charge while driving results in serious inconvenience even comparable to vehicle breakdown, as an effect of long fuel recharging times and lack of charging facilities. As a result, the dimensioning of the energy subsystem of an EV is a crucial activity. The choice of the power components and of the adopted policies should thus be validated at design time through simulations, that estimate the vehicle driving range under reference driving profiles. It is thus necessary to build a simulation framework that takes into account an EV power consumption model, dependent on the characteristics of the vehicle and of the driving route, plus accurate models for all power components, including batteries and green power sources. The goal of this paper is to achieve early EV simulation, so that the designer can estimate at design time the driving range of the vehicle, validate the adopted components and policies and evaluate alternative configurations.

2023

to help with energy efficiency and Reduction of carbon. Electric vehicles (EVs) are eclipsing traditional IC engine vehicles in terms of market capitalization. The popularization of EVs leads to an increase in the number of charging points, which has a significant impact on the power grid. Various charging strategies and grid integration methods are being developed in order to mitigate the negative effects of EV charging and to maximize the benefits of EV grid integration. The article presents the projected greenhouse gas emissions for transportation system, as well as the existing EV status and a thorough review of EV charging, the types of chargers being used, types of batteries used, types of WPT used and the key future developments being made on a global and Indian scenario. Lastly, the challenges and recommendations for future EV charging development are summed up.

2010

Development of electric vehicle architectures requires complex analysis and innovative designs in order to produce a highly efficient mode of personal transportation acceptable to the target demographic. Using computer-aided modeling and simulation has been proven to decrease the development time of conventional vehicles while increasing overall success of the product design. Computer-aided automotive development also allows a fast response to the testing and inclusion of developing technologies in individual systems. Therefore, it follows to use this technique in the research and development of electric vehicles for consumer markets. This paper presents a system level model development and simulation for an electric vehicle using the Matlab-Simulink platform and its associated process. The current state of the art technologies for electric and plug-in hybrid electric vehicles are given to provide an introduction into the subject. Following, the project development is briefly described, detailing the specific goals for the project and the methods by which results were achieved. Next the paper discusses the analytical and simulation models for each key component as divided by the following systems: battery, charging, and traction. Model assembly and the development of a graphic user interface follows. Finally, the testing procedures for model validation, along with results, and future project works are provided.

2018

Research related to EV modeling in MATSim started in 2008/2009, with an electricity grids project (Waraich et al., 2013d); it's goal was to uncover potential bottlenecks and/or constraint violations in Zürich city's lower voltage grid due to future EV charging. A framework emerged from the research for EV modeling, called TESF (Transportation Energy Simulation Framework) (Waraich et al., 2014a). This resulted in various framework extensions and enabled simulation of various scenarios (Waraich et al., 2014a; Waraich, 2013; Abedin and Waraich, 2014; Schieffer, 2011; Galus and Andersson, 2011; Galus et al., 2012a; Bischoff, 2013; Bischoff and Maciejewski, 2014). This chapter provides advice on these research directions and serves as a starting point for modeling EVs in MATSim.

IRJET, 2022

In present scenario, air pollution has become a serious concern for the India. According to recent global report many cities in the India are most polluted cities. Major sector contributing to the air pollution are industrial sector and transport sector. Among this 51% of air pollution is caused by the industrial sector and 27% by electric the transport sector. Air pollution contributes to the premature deaths of 2 million Indians every year. In order to minimize the air pollution, vehicle (EV) can act as blessing in lowering the GHG (Green House Gases) emission. Electric as decreasing the pollution level and reduction in oil bills etc. Although there is considerable amount of threats in establishing the electric vehicles types of motor used for electric vehicles, batteries, and Architecture of Electrical vehicle in India

International Journal on Smart Sensing and Intelligent Systems

This paper reviews the battery technology, methods of charging techniques for charging the EV's battery, factors affecting the EV adaptation, India. Many significant methods recently used in electric vehicles are explained. In India, it has taken a major step in adapting the electric vehicle employing the Faster Adoption and Manufacturing of (Hybrid &) Electric Vehicles in India (FAME) scheme a government initiative. In the forthcoming years, electrification of transportation networks is a basic one while considering the consumption of petroleum derivatives just for the 50 years. Transportation is the most important source of logistics, and people contribute significant primary emissions to global warming, so avoid this situation by focusing on zero emissions. Transportation by electric vehicle is the lone achievable answer for these issues. This paper presents the effect of quick charging on Lithium-ion batteries in EVs. The Lithiumion battery is utilized to be essential energy...

international journal for research in applied science and engineering technology ijraset, 2020

Growing population increases the problem of growing pollution all over the globe. Population in India is about 135 crores and this number suggests the amount of pollution caused knowingly or unknowingly. Over the few decades it has been observed that the largest contributor to the pollution in India is the use of large numbers of automobiles or vehicles. Electric Vehicles prove to be one of the most efficient replacements to the fueled automobiles. These are just another automobiles or vehicles but run on electric power or electrical energy. This paper reviews the state of art of the electric vehicle concept, its advantages and benefits to the society and its power management strategies.

Lecture Notes in Mobility, 2015

The Project ASTERICS, an international EU-STREP Project with 10 partners from 7 countries, follows the target to increase the efficiency of fully electric vehicles (FEV) by means of improved virtual models and intelligent testing and verification methods. Better models in the early design-and development phases allow more realistic and improved concept studies and hence detailed optimization at component level as well as global optimization at system level. Through intelligent testing methods it will be possible to enhance the model quality on one hand and reduce the test time on the other hand. These testing methods shall also allow the assessment of durability and ageing effects for electrical components in the FEV-driveline. The combination of virtual simulation with realistic, for FEV relevant driving cycles leads to a very good possibility for optimization of predictable mileage. In this paper the results of the first phase of the ASTERICS project are presented. It describes the modelling approach and gives a good overview on virtual product development by means of model based system engineering (MBSE). Also described is the methodology to identify design goals based on real life data through assessment and definition of a representative driving cycle for FEV.

Proceedings of the 17th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Industry, Innovation, and Infrastructure for Sustainable Cities and Communities”, 2019

SIDS (Small Island Developing States) are unique in their drive to reducing GHGs. Since these countries need to be self-sufficient in energy, there is a dilemma on the best way to reduce GHG while maintaining energy security. One way would be to drive the implementation of EVs for the transportation sector. However this can wreak havoc on the SIDS electrical network if not done properly. This paper reviews the possible effects of introducing EV charging on the grid. The authors have given Policy recommendations as to how EV penetration can be managed whilst maintaining the reliability and quality of the electricity grid. The authors also suggest a unique controller that can be used by the utility to limit charging time and window.

Energies

As fuel consumption in the transport sector has increased at a faster pace than in other sectors, the use of electromobility represents the main strategy adopted by the automotive industry. In this context, as the number of electrical vehicles (EVs) will increase, it will also be necessary to increase the number of charging stations. The present paper presents a complete solution for charging stations that can be located in the office or mall parking area. This solution includes a mode 3 AC charging stations of International Electrotechnical Commission (IEC) 61851-1 Standard, an EV simulator for testing the good functionality of the charging stations (i.e., communications, residual-current device (RCD) protection) and a software application used for controlling the charging process by the programmable logic controller (PLC).

e-ISSN: 2320-9801 | p-ISSN: 2320-9798

**INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH**

**IN COMPUTER & COMMUNICATION ENGINEERING**

**Volume 11, Issue 5, May 2023**

**Impact Factor: 8.379**

EVSE Simulator: A backbone for EV Infrastructure

1 Darshan Patel, 2 Tirth Patel, 3 Shail Rami, 4 Het Patel, 5 Prof. Nirav Mehta, 6 Dr. Anwarul Haque

1 UG Student, Power Electronics Dept., VGEC, Chandkheda, Ahmedabad, Gujarat, India

2 UG Student, IT Dept., SPEC, Vasad, Anand, Gujarat, India

3 UG Student, Power Electronics Dept., VGEC, Chandkheda, Ahmedabad, Gujarat, India

4 UG Student, Power Electronics Dept.,VGEC, Chandkheda, Ahmedabad, Gujarat, India

5 Assistant Professor, Power Electronics Dept., VGEC, Chandkheda,Ahmedabad, Gujarat, India

6 Assistant Professor, Power Electronics Dept., VGEC, Chandkheda,Ahmedabad, Gujarat, India

Abstract

In developing country like India automotive industry growing rapidly. Growing automotive industry create pollution so government is taking initiative to curb the pollutions through Electric Vehicles. Electric vehicles (EVs) produce zero emissions at the tailpipe, which means that they do not release any pollutants or greenhouse gases into the air. This is in contrast to traditional gasoline-powered vehicles, which are a major source of air pollution and contribute to climate change. By reducing air pollution, EVs can help to improve air quality and protect the health of both humans and wildlife.However, one of the challenges with EV charging infrastructure in India is the lack of a comprehensive and coordinated strategy for its development. Currently, there are a number of different players involved in the development and operation of charging infrastructure, including government agencies, private companies, and electric utilities. This can lead to a fragmented and unevenly distributed charging network, which can be a significant hindrance for EV owners.Manufacturing of Electric vehicle supply equipment(EVSE) is complicated but its more complex to simulate therefore EVSE manufacturer want proper simulator that can measure the capacity, duty cycle, frequency and state change of it. This article includes all the parameter that EVSE manufacture want that can measure by simulator.

KEYWORDS: EVSE simulator, frequency measurement, EV Chargers, Voltage measurement, Duty Cycle

I. Introduction

Electric Vehicle Supply Equipment (EVSE) is a vital component of the infrastructure required to support the growth of electric vehicles (EVs). It provides a safe and reliable means of recharging EVs by acting as an intermediary between the electric grid and the EV’s battery. There are different types of EVSEs available, such as Level 1, Level 2, and DC fast charging, each with their own charging rates and capabilities [9].However, one of the significant challenges in the development of it ensuring their compatibility and interoperability with EVs from different manufacturers. Therefore, it is essential to conduct thorough testing and validation of the charging systems to ensure their functionality, reliability, and safety [1]. It is cost-effective and efficient way to test and validate it before deployment.Most of the people think that EVSE work as phone charger. Electric Vehicle Supply Equipment (EVSE) and phone chargers are two very different types of chargers that serve different purposes. The main differences between EVSE and phone chargers are as follows:

- Power Rating:Itis designed to deliver a much higher power output than phone chargers. This is because EV batteries have a much larger capacity and require a higher amount of power to recharge. In contrast, phone chargers typically deliver lower power outputs to charge the smaller batteries in mobile devices.

- Charging Time:It takes much longer to charge an electric vehicle than phone chargers take to charge a mobile device. This is due to the larger battery capacity of EVs and the higher power output required to recharge them. In contrast, phone chargers can typically charge a mobile device in a few hours or less.

International Journal of Innovative Research in Computer and Communication Engineering

| e-ISSN: 2320-9801, p-ISSN: 2320-9798| www.ijircce.com | |Impact Factor: 8.379 | || Volume 11, Issue 5, May 2023 ||

| DOI: 10.15680/IJIRCCE.2023.1105070 |

3. Charging Protocol: EVSEs use specific charging protocols, such as the SAE J1772 or CHAdeMO, to communicate with the EV’s onboard charger and safely transfer power to the battery. In contrast, phone chargers typically use universal charging protocols, such as USB or Lightning, to transfer power to the device.

4. Safety Features:It have several safety features, such as ground fault protection and overcurrent protection, to ensure the safe and reliable operation of the charging system. In contrast, phone chargers may not have the same level of safety features and may pose a risk of electric shock or fire if used improperly.

An EVSE simulator is a device designed to replicate the operation of a real charging station, allowing for various charging scenarios to be simulated. This simulation ensures that the EVSE is compatible and interoperable with different EVs.simulators are used to test the EVSE’s communication protocols, safety features, and charging capabilities. Moreover, they can also simulate different charging scenarios, such as low voltage or high voltage conditions, to test the response under different conditions [4]-[6].

In this research paper, we will discuss the significance of EVSEs in supporting the growth of EVs and the challenges faced in their development. We will explore the role of simulators in testing and validating the charging systems and how they ensure compatibility and interoperability of the EVSE with different EVs. Furthermore, we will delve into the different types of EVSE simulators, their features and applications in testing and validating EVSEs [7], [8].

A. Fundamental of EVSE:

EVSE is the infrastructure that provides electrical energy to charge electric vehicles (EVs). An EVSE typically consists of a charging station, a connector, and an interface between the station and the EV’s onboard charger. The charging station provides the electrical energy to the EV’s battery, and the interface communicates with the EV’s onboard charger to ensure safe and efficient charging.EVSEs come in various types and power levels, from Level 1 (120-volt AC charging) to Level 2 (240-volt AC charging) to Level 3 (DC fast charging). Level 1 charging is typically done using a standard household electrical outlet, while Level 2 and Level 3 charging require special charging stations that provide higher power outputs.EVSEs can be installed in a variety of locations, such as residential homes, commercial buildings, and public charging stations. They play a critical role in the adoption and growth of electric vehicles by providing a reliable and convenient way to recharge EVs [3], [9], [10].

B. EVSE Charging Plug:

The charging plug used by EVSE can vary depending on the type of connector and charging protocol used by the EV and the EVSE [2], [11]-[13]. Some common typescharging plugs include:

- SAE J1772: This is the most common charging plug used in North America and is used by most EVs produced by American and Asian automakers. The plug consists of five pins and is designed to deliver up to 80 amps of current.

- CCS (Combined Charging System): This plug is a DC fast charging plug used by some EVs produced by American and European automakers. It combines the standard J1772 plug with two additional pins for high-power DC charging.

- CHAdeMO: This is a DC fast charging plug used by some EVs produced by Japanese automakers. It consists of a large, round plug that delivers up to 125 amps of current.

- Tesla Supercharger: This is a proprietary DC fast charging plug used by Tesla vehicles. It consists of a rectangular plug that delivers up to 250 amps of current.

In addition to the physical plug, EVSEs also use a variety of communication protocols to communicate with the EV’s onboard charger and ensure safe and reliable charging. These protocols include CAN bus, Power Line Communication (PLC), and Ethernet.

[ e-ISSN: 2320-9801, p-ISSN: 2320-9798] www.ijircce.com | |Impact Factor: 8.379 |

Fig.1. AC & DC Connector Type

C. GUN PIN DIAGRAM: -

Fig. 2. Gun Pin Diagram

Table 1 Pin Description

| PIN | DESCRIPTION |

|---|---|

| L1 | AC line 1 |

| N | AC Neutral |

| PE | Protective Earth (Ground) |

| PP | Proximity Pilot /Plug Present, which provides a signal to the vehicle’s control system so it can prevent movement while connected to the electric vehicle supply equipment, and signals the latch release button to the vehicle. |

| CP | “Control Pilot” is a communication line used to signal charging level between the car and the EVSE, and can be manipulated by vehicle to initiate charging as well as other information. The signal is a 1 kHz square wave at ±12 volts generated by the EVSE to detect the presence of the vehicle, communicate the maximum allowable charging current, and control charging begin/end. |

II. NEED OF EVSESIMULATOR

An EVSE simulator is a tool used to simulate the behaviour of an electric vehicle charging station. An EVSE simulator is a valuable tool for anyone working with electric vehicle charging stations, whether it will be for testing, training, development, or research purposes. There are several reasons why it might be necessary, including:

- Testing:it is used to test the functionality of electric vehicle charging stations. They can be used to test whether a charging station is working correctly and whether it is delivering the correct amount of power to an electric vehicle.

- Training:it can be used to train electric vehicle service technicians on how to troubleshoot and repair electric vehicle charging stations.

Fig. 3. Flowchart of the System

3. Development:it can be used to develop new electric vehicle charging station technologies. By simulating the behaviour of a charging station, engineers can test and refine new technologies before deploying them in the real world.

4. Research:it can be used for research purposes, such as studying the impact of electric vehicles on the power grid or investigating the effectiveness of different charging station designs.

III. ALGORITHM

When the Gun of EVSE either in our hand or not connected to car then EVSE’s screen indicates normal blue light and voltage in gun’s pin across CP and PE pin it is 12 V . Secondly, when user connect gun with car and car connected properly then screen of it indicates yellow icon and voltage level id 9 V . Thirdly, when user reach payment interface then voltage level are 9 V PWM after complete imbursementEVSE simulator trip the relay and charging starts successfully and voltage level are 6V PWM. Simulator detect all state change and respond capture and give proper

International Journal of Innovative Research in Computer and Communication Engineering

| e-ISSN: 2320-9801, p-ISSN: 2320-9798| www.ijircce.com | |Impact Factor: 8.379 |

|| Volume 11, Issue 5, May 2023 ||

| DOI: 10.15680/IJIRCCE.2023.1105070 |

output like frequency conversation duty cycle measure and also identify the rating of EVSE. Accordingly every output simulator shows every response on its screen. Fig 3 illustrates the Flow chart of system.

IV. SYSTEM ARCHITECTURE

The hardware elements of an EVSE simulator, such as a microprocessor, power supply, and interface circuits, make up its usual system design. The software components of an EVSE simulator typically include firmware that controls the hardware components and simulation software that models the behaviour of EVs and EVSEs. The system architecture seeks to ensure the dependability and safety of EVSEs and EVs by properly simulating real-world charging circumstances. We take analog and digital signal from EVSE’s CP pin. Fig. 4 shows the block diagram of the system.

Fig. 4. Block diagram

A. ATmega328: -

ATmega328 is a heart of EVSE simulator. For continuous analog and digital signal analysis Microcontroller unit (MCU) plays vital role in it. Moreover, LCD interfacing is also depending on MCU.It has a 32 KB flash memory, 2 KB SRAM, and 1 KB EEPROM. The ATmega328 has an 8-bit RISC architecture and operates at a clock frequency of up to 20 MHz It is widely used in various applications, including industrial automation, robotics, and consumer electronics. In this project it will continuously measure voltage through voltage divider on analog pin as well as frequency on digital pin. It is also capable to show different output based on voltage on LCD display. ATmega328 shown in Fig. 5.

Fig.5. ATmega328

Fig. 6. 16∗2 LCD

Fig.7. LM2596

Fig.8. SMPS

B. 16∗2 LCD display: -

A 16×2 LCD is a liquid crystal display (LCD) module that can display up to 16 characters per line and up to 2 lines of text. For display State changes, Duty cycle and rating etc. we used this display in our project.A 16∗2 LCD is shown in Fig. 6.

C. LM2596: - Buck Converter:

The LM2596 module is a voltage regulator module based on the LM2596 integrated circuit (IC). The LM2596 is a step-down (buck) switching regulator IC that can convert higher voltage DC power into lower voltage DC power rather than showing IC and its peripheral, we can visualize whole module in Fig. 7.

D. Switched Mode Power Supply:

Switched Mode Power Supply (SMPS), is a type of power supply that uses high-frequency switching to convert electrical power from one form to another. The main advantage of SMPS over traditional linear power supplies is their high efficiency, compact size, and low heat generation. In our project we use SMPS for converting the input power supply to the required output voltage and current levels. They use a switching regulator to efficiently convert the DC voltage from the power source to the desired voltage and components. In our case it will convert 220V AC Supply into 12 V DC supply. A SMPS which used in project is shown in Fig. 8.

E. Relay with driver circuit:

Relay is an electromechanical switch which can only operate by signal which one fed by MCU. In EVSE simulator we use relay for automation purpose.Relays play a crucial role in the EVSE simulator by controlling the flow of power to the simulated EV. Relay will operate according to EVSE state change and relays also protect the EV and the EVSE from damage due to overvoltage, overcurrent, or short circuits. Its precise and reliable operation ensures the safety and accuracy of EVSE simulations. For driving relay separate driver circuit needed which is shown in Fig. 9 .

Fig.9. Relay Driver Circuit

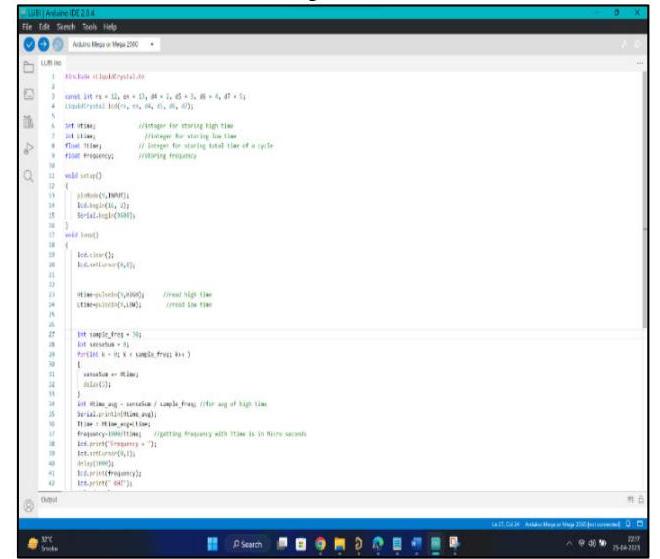

F. Software toolsArduino IDE:

The Arduino Integrated Development Environment (IDE) is an open-source software tool used for programming and developing Arduino boards. It provides a user-friendly interface for writing, compiling, and uploading code to Arduino boards. The IDE supports various programming languages, including C++, and offers a wide range of libraries and examples to facilitate development. The IDE is cross-platform and can run on Windows, Linux, and macOS. Its simplicity, versatility, and community support make it a popular choice for hobbyists and professionals alike in the development of embedded systems. Fig. 10 shows Arduino IDE window.

V. SYSTEM IMPLEMENTATION

The prototype can be divided into four major functional parts.

A. Control circuit

International Journal of Innovative Research in Computer and Communication Engineering

| e-ISSN: 2320-9801, p-ISSN: 2320-9798| www.ijircce.com | |Impact Factor: 8.379 |

|| Volume 11, Issue 5, May 2023 ||

| DOI: 10.15680/IJIRCCE.2023.1105070 |

This part serves as the brain of the EVSE Simulator. ATmega328P accepts the signal coming from the sensing circuit and is responsible for the control and coordination of all the different components used in the project. Fig. 11 show the PCB layout of the control circuit as well as final PCB.

B. Sensing unit

For frequency and constant voltage measurement we have made sensor from various voltage divider circuit. signal pass through voltage divider and divider gives output to MCU.

C. Display/status indicator unit

State change of EVSE, frequency, duty cycle and EVSE rating and other relevant data displayed to the user on LCD (Liquid Crystal Display).

D. Power circuit

It includes a 3.3 V and 12 V power supply which is required to power the MCU and display. The circuit is simple andit includes a SMPS, capacitors used as filters and voltage regulators.

Fig. 10. Arduino IDE program

Fig. 11. PCB of simulator

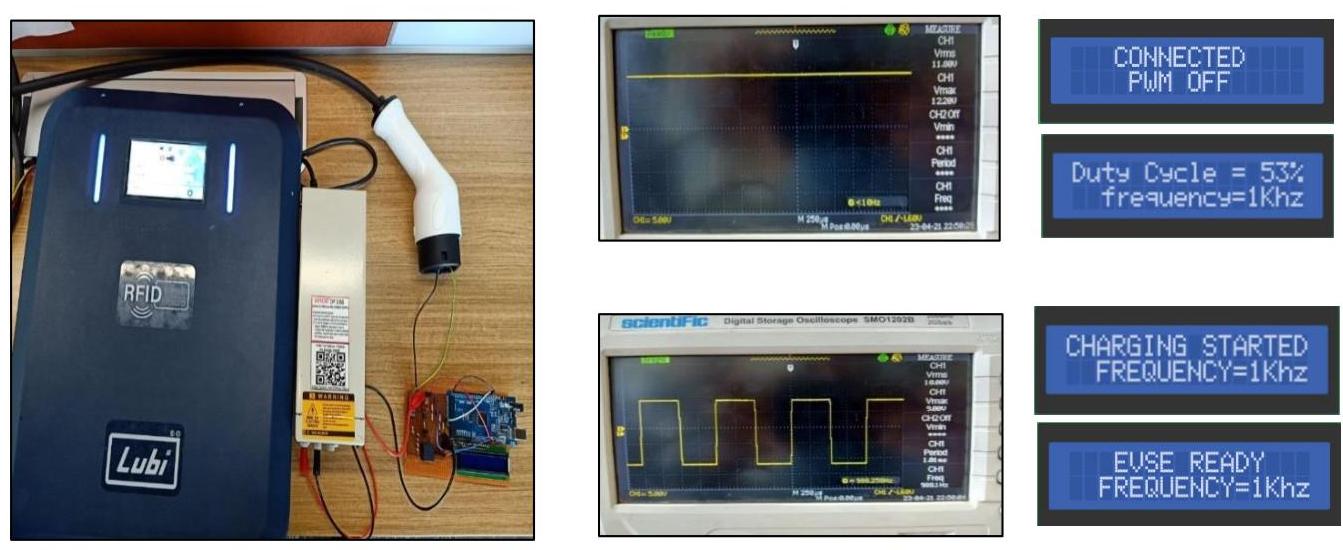

VI. TEST RESULTS

The final result and analysis we obtain by testing the product was quite productive and with no errors after several testing and analysis. Fig 12 shows the test setup and the results. The various result analysis is shownthroughthe figures givenbelow:

Fig. 12. Test Setup and results on simulator screen (Courtesy by: Lubi Industries LLP, Gujarat, India)

VII. CONCLUSION AND FUTURE WORK

The development of an EVSE simulator is an important step towards the wider adoption of electric vehicles. This simulator can be used to test and evaluate different charging scenarios, which can help in the design and implementation of more efficient and reliable EVSE infrastructure. The research paper illustratesthe effectiveness of the proposed simulator. The simulator provides a realistic environment for testing various charging scenarios, and it can help in identifying potential issues before they occur in real-world scenarios. The prototype is still in its early stages and a lot of work still needs to be done. There are several limitations of EVSE simulator which is compatible with all AC Standards but not compatible with DC chargers. Secondly, due to the constant power supply, it may get damage due to overheating or power supply may get off. Thirdly, we can replace 10-bit MCU. Moreover, we can add new functionality like Ground Fault Detection Features and Over Current measurement features.

REFERENCES

- Ali Bahrami, EV Charging Definitions, Modes, Levels, Communication Protocols and Applied Standards, Research gate (2020).

- SAE, J1772_201210, “SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler J1772_201710”, 2017.

- G. Lee, T. Lee, Z. Low, S. H. Low and C. Ortega, “Adaptive charging network for electric vehicles”, Proc. IEEE Global Conf. Signal Inf. Process., pp. 891-895, Dec. 2016.

- J. C. Mukherjee and A. Gupta, “A review of charge scheduling of electric vehicles in smart grid”, IEEE Syst. J., vol. 9, no. 4, pp. 1541-1553, Dec. 2015.

- Z. J. Lee, S. Sharma, D. Johansson and S. H. Low, “ACN-Sim: An Open-Source Simulator for Data-Driven Electric Vehicle Charging Research,” in IEEE Transactions on Smart Grid, vol. 12, no. 6, pp. 5113-5123, Nov. 2021, doi: 10.1109/TSG.2021.3103156.

- Q. Wang, X. Liu, J. Du and F. Kong, “Smart charging for electric vehicles: A survey from the algorithmic perspective”, IEEE Commun. Surveys Tuts., vol. 18, no. 2, pp. 1500-1517, 2nd Quart. 2016.

- Z. J. Lee, T. Li and S. H. Low, “ACN-data: Analysis and applications of an open EV charging dataset”, Proc. 10th ACM Int. Conf. Future Energy Syst., pp. 139-149, 2019.

- Xuesong Zhou, Youjie Ma, Lei Zou, Zhiqiang Gao, The current research on electric vehicle, IEEE2016.

- Electric Vehicle Supply Equipment (EVSE)" by U.S. Department of Energy: https://www.energy.gov/eere/electricvehicles/electric-vehicle-supply-equipment-evse

- Level 1, Level 2, or Level 3? EV Chargers Explained (howtogeek.com)

- BIS standards for electric vehicle charging: BIS_17017

- J1772 EV Simulator | Hackaday.io

- Charging Interfaces ∣ Vector

**INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH**

**IN COMPUTER & COMMUNICATION ENGINEERING**

www.ijircce.com

References (13)

- Ali Bahrami, EV Charging Definitions, Modes, Levels, Communication Protocols and Applied Standards, Research gate (2020).

- SAE, J1772_201210, "SAE Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler J1772_201710", 2017.

- G. Lee, T. Lee, Z. Low, S. H. Low and C. Ortega, "Adaptive charging network for electric vehicles", Proc. IEEE Global Conf. Signal Inf. Process., pp. 891-895, Dec. 2016.

- J. C. Mukherjee and A. Gupta, "A review of charge scheduling of electric vehicles in smart grid", IEEE Syst. J., vol. 9, no. 4, pp. 1541-1553, Dec. 2015.

- Z. J. Lee, S. Sharma, D. Johansson and S. H. Low, "ACN-Sim: An Open-Source Simulator for Data-Driven Electric Vehicle Charging Research," in IEEE Transactions on Smart Grid, vol. 12, no. 6, pp. 5113-5123, Nov. 2021, doi: 10.1109/TSG.2021.3103156.

- Q. Wang, X. Liu, J. Du and F. Kong, "Smart charging for electric vehicles: A survey from the algorithmic perspective", IEEE Commun. Surveys Tuts., vol. 18, no. 2, pp. 1500-1517, 2nd Quart. 2016.

- Z. J. Lee, T. Li and S. H. Low, "ACN-data: Analysis and applications of an open EV charging dataset", Proc. 10th ACM Int. Conf. Future Energy Syst., pp. 139-149, 2019.

- Xuesong Zhou, Youjie Ma, Lei Zou, Zhiqiang Gao, The current research on electric vehicle, IEEE2016.

- Electric Vehicle Supply Equipment (EVSE)" by U.S. Department of Energy: https://www.energy.gov/eere/electricvehicles/electric-vehicle-supply-equipment-evse

- Level 1, Level 2, or Level 3? EV Chargers Explained (howtogeek.com)

- BIS standards for electric vehicle charging: BIS_17017

- J1772 EV Simulator | Hackaday.io

- Charging Interfaces | Vector

Darshan Patel

Darshan Patel